Lean management

Want to optimize your performance while taking your teams on the adventure? With Apilean, become actors of your own transformation.

Our Lean management consulting firm takes into account the specificities of your sector (pharma, automotive, services, etc.) and your differences.

We accompany you with a tailor-made approach through your improvement process thanks to a unique approach to both global and human performance.

Our main actions

Need to accelerate continuous improvement and adapt… Change is part of our daily lives! Discover our Happy Lean approach for results and lasting impact.

Diagnosis

Identify the actions that will impact your operational performance most quickly and sustainably

Operational excellence

Create or improve your operational excellence system and organize skill building

Continuous improvement

Boost your performance with concrete actions on the ground while making you autonomous

Vision of the future

Planning the necessary next steps for a 4.0 plant or future service

Benchmarking

Organize factory or company tours to see global best practices and inspire others

New management methods

Make operational teams accountable and autonomous by changing managerial positions

We develop your operational excellence

Apileaners are experienced consultants that know what it’s all about when they talk about operational excellence. Listening to you, they chart the way with you towards your desired performance goals and make you autonomous.

The key steps of an advisory mission with Apilean

Diagnose

Field measurement of your Lean maturity level

Identify constraints that slow down your processes to satisfy internal and external customers

Definition of the most impactful leads according to your ambition

Motivate

Envy is a powerful engine!

Sharing global best practices

Embarkation and accompaniment on the GROUND of the stakeholders with small victories

Creation and monitoring of conditions for success and change management

Anchor

Coaching managers to have the right reflexes

Establish organizational and management rituals to ensure sustainable and responsible performance

Long-term support for long-term sustainability

examples of commonly achieved results with our clients

Industry

- Reduce surfaces by 30%

- Divide your flow time by 10

- Divide by 15 the distance produced

- Divide by 2 your outstanding amounts

- Multiply your problem resolutions by 10

- Reduce problem resolution times by 3

- Reduce your quality problems by 3

- Increase your productivity by 30%

- Improving employee satisfaction (survey)

Services

- Divide your process times by 3

- Divide by 2 your outstanding invoices

- Multiply your problem resolutions by 10

- Reduce your quality problems by 3

- Improve customer satisfaction rate

- Increase your productivity by 30%

- Improving employee satisfaction (survey)

- Doubling the number of improvement projects

- Reducing the carbon footprint

Our commitment

From half-day to support over several months in France and abroad, remotely or in person, we put everything in place to boost the performance of your company or your service, while making you keep a smile.

At your side to optimize your performance

Drive your operational performance

- KPIs analysis

- Industrial diagnosis

Levels of industrial maturity - Break-up strategy development

Search of actions with a direct impact on economic performance - Reporting and performance indicators Implementation

- Deployment of objectives (Hoshin Kanri, matrix in X…)

- Short Interval Animations (AIC) Implementation : top 5, top 30, production meeting…

Deploy your production system

- Lean diagnosis and associated management system

- Building your Lean maturity levels

- Benchmarking organisation

- Construction of the production system and its toolbox

- Animation of a global production system

- Training and facilitation of a network of Lean facilitators and relays

- Establishment of a central structure Production System

Increase the efficiency of your machines

- Implementation of TPM procedures

- Implementation of the MPM approach

identification of penalizing machines in order to quickly improve OEE (or TRS) - Improvement and rationalization of maintenance activities

- Development of the autonomy of field teams

- Stand-alone maintenance

- Preventive maintenance

- Loss analysis

- Professionalization of maintenance teams

- Project capitalization

- Project reliability

Have autonomous organizations

- Establishment of autonomous units

- Stages of autonomy (exclusive roadmaps)

- Deployment of accountability

- Organizational Diagnostic (8S)

- Change Coaching

Change the image & visual of your entities

- Implementation of 5S projects

- Implementation of the necessary visual management

- Sustainability of the approach by changing behaviour

- Analysis of video reports on global best practices

Reduce your delivery times

- Flow analyses (VSM)

- Just in time

- Improvement of the Supply Chain

- Supply Management

- Kitting optimization (ninja eye method)

- Reduction of change times (SMED)…

Manage on a daily basis

- Standardisation

- I Do, We Do, You Do Training

- TWI approach

- Kaizen construction sites 2 hours or 2 days

- Visual management

- Yards 5S

Solve your problems sustainably

- Implementation of quality animation rituals (QRQC)

- Deployment of problem solving methods

- Building a culture of customer protection

- Quality tools management (A3, QC Story, MQA, 8D, etc.)

- Development of standardisation

CDMA - Operator training

Improving health & working conditions

- Construction of a real strategy Safety, Health and Working Conditions

- Simplified ergonomic analysis of workstations

- Reduction of MSDs

- Repositioning man in the center of a Lean system

Design (or redesign) of your plants

- Putting online

- Realize your Hoshin flows

- Factory relocation

- Selection and design of Model Line

- Reduction of distances and delays

- External look at your factory creation projects

Involve your managers

- Setting up autonomous teams and cross-functional groups

- Establishment of managerial training courses

- Setting up individual support for each manager

- Integration of intergenerational into the organisation

- Journey for Team Leaders

- The manager coach

- The leader manager

- Organise a soft skills policy

Moving towards the factory 4.0

- Awareness of concepts Industry of the Future: Human factory, connected factory, automated factory, frugal factory, extended factory, innovative factory, agile factory, integrated factory…

- Diagnosis of the current situation and implementation of the prerequisites (organisational and technical)

- Contact with partners: mobile applications, augmented reality, robots & robots, SQVT, 3D printing…

Our lean approach

Every company is different. They each have their own strengths, weaknesses, particularities, management methods, culture, etc. some are very large, some are very small…some are in industry, some are in tertiary—

In short, all our customers are different and therefore deserve special treatment.

The Happy Lean approach

Performance is achieved with motivated and competent people who are part of a project in which they believe. To make them committed actors, we intervene:

As a collective

through worksites, trainings, team work, facilitation and collective intelligence sessions, workshops, group coaching, external benchmarking…

Individually

by changing certain behaviour or reflexes during field support, or by doing more properly a work of personal coaching, with small steps…

Our happy customers testify

A 3-year partnership on the empowerment of teams, a professional, committed, motivating and warm support team. Results that match our expectations, the perfect combination of operational excellence expertise, staff development, Lean and soft skills.

David Dechirot

Plant Manager, SAINT GOBAIN SEKURIT

Apilean’s ability to lead, their deep knowledge of Operational Excellence practices, and their transposition into our context have allowed us to pass significant maturity caps at the Lean and Industry 4.0 level. Thank you for this always cheerful collaboration.

Samuel Davron

Industrial & Excellence Director, SONCEBOZ

A few words come to mind when thinking “Apilean”: Good mood, Energy, Expertise, Simplicity, Experience sharing, Networks …

Julie

Lean Manager, WATCHMAKING sector

We appreciate the cooperation with Apilean and its Apileaners because of their professionalism and adaptability. They also bring us real expertise in the field of learning, complementary to what we have internally.

Ilona

Manufacturing Academy Manager, RENAULT

APILEAN and Carlos’ teams have been supporting us for several years in the deployment of continuous improvement tools. The approach is not new in the industry, but the pedagogy of APILEAN and the structured method based on communication and understanding of “Gemba” have allowed us to implement simply tools like 5S in our workshops but also a dynamic of improvement and visual management of our industrial performance with the QrQc Factory and QrQC line. These tools are now standards within CATU and are gradually being rolled out to all companies in the group.

Kamel Sedrati

Industrial Director, CATU & SICAME Group

Some live examples!

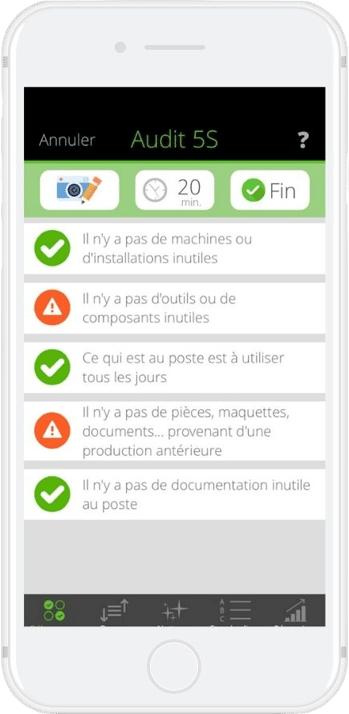

Our Lean Apps

Well-targeted applications

Improve the desire to do and practice

Increase the speed of execution

Improve your image with your customers

Reduce the amount of paper used

2 applications available

Lean Observe : improve the workstations and strengthen the role of the local manager

Lean 5S : simplify 5S audits in the field

Offre One Day Digital

Experience and discover the usefulness of apps for an entire day. Improve your performance by involving your teams in a new way.

Bonus: autonomous at the end of the day, you keep the IPAD with the installed apps!

Tailor-made

Apilean supports you to advise you and develop applications that promote performance in an industrial environment and then train users in their use.